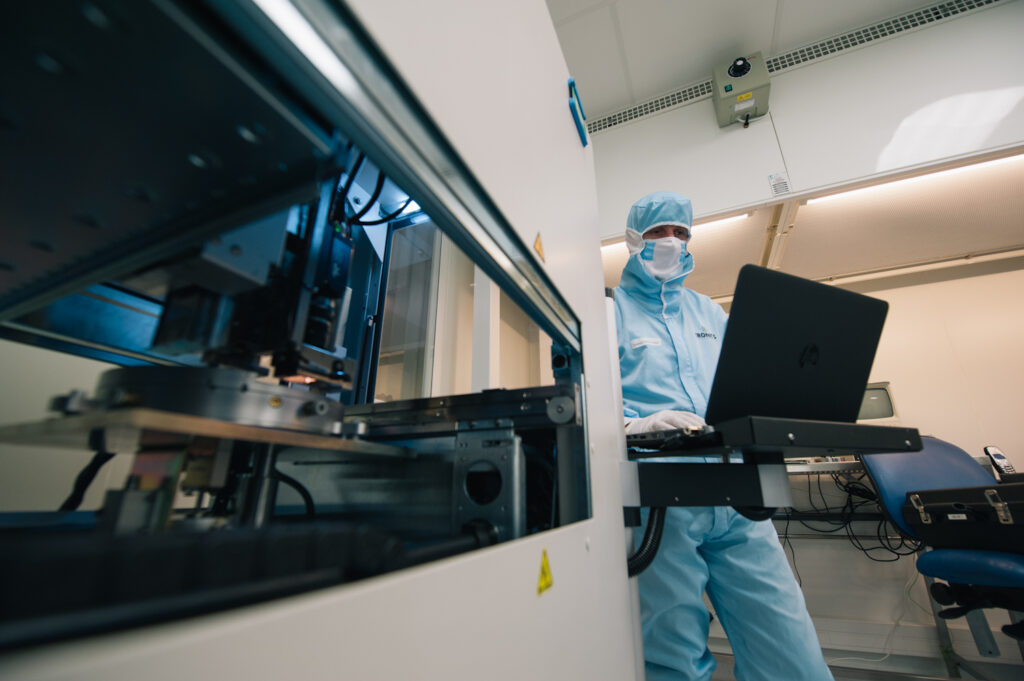

Inertial MEMS Production

At Tronics, manufacturing is deeply rooted in our culture. We have established our production facility in 2003 in Crolles, near Grenoble, France, in the heart of the French Silicon Valley, at proximity of ST, Soitec, Schneider Electric, Thales Avionics, Lynred, Teledyne, CEA-Leti, and many others.

MEMS wafer fabrication, assembly, packaging, calibration and test under one roof

To ensure a consistent quality and to secure deliveries of our accelerometers and gyrometers for our customers we have integrated all inertial MEMS sensors manufacturing capabilities in-house; MEMS Front-End wafer processing, assembly, packaging, calibration and test. This gives us the capacity to provide faster response time to customers’ demands. This also enables us to consistently monitor quality and to easily track possible failure and their root cause in the production line.

MEMS Front-End, Back-End

and Test

- 2,500m² buildings encompassing:

- 600m² class 10 to 1000 MEMS production clean rooms for 6” / 150mm Si, SOI and glass wafers

- 200m² class 1000 to 10000 clean room for assembly and packaging of MEMS and IC

- 200m² test and calibration lab

- Integrated IT Manufacturing Execution System

- IATF16949, ISO14001, ISO45001 and ISO50001 certified

We possess a complete portfolio of equipment dedicated to inertial MEMS devices production. This includes the following capabilities.

Front-End: MEMS wafers processing

- Stepper and double-side contact lithography

- DRIE and RIE dry etching

- KOH & TMAH etching

- Dielectrics deposition

- Thin film metal deposition including getter deposition

- Electroplating

- Wafer bonding (SDB, eutectic, thermo-compression, anodic bonding)

- Metrology& In-line Control

Back-End: MEMS & IC assembly

and packaging

- Static and dynamic wafer level tests

- Thinning/Polishing, Dicing

- Die attach

- Wirebonding

- Package sealing including high vacuum sealing with getter

- Component- level test and calibration

Calibration & Test

- Reliability and functional tests

- Inertial sensors trimming and calibration