High stability digital MEMS gyros

GYPRO® is a unique family of high performance closed-loop digital MEMS gyroscopes housed in a SMD package. While open-loop MEMS gyros tend to demonstrate poor performances in harsh conditions, the built-in force-rebalance architecture makes our GYPRO® high stability MEMS gyros extremely linear and insensitive to vibrations and linear accelerations.

High performance MEMS gyros for dynamic applications

Leveraging a best in-class vibration rejection, excellent bias stability and Angular Random Walk (ARW), GYPRO® is the perfect candidate for precision attitude and angular rates measurement in demanding environments.

The superior bias stability, scale factor repeatability and low latency make GYPRO® an industry-leading sensor solution to build IMU (Inertial Measurement Unit) for high performance attitude and motion control systems as well as INS (Inertial Navigation Systems) for GNSS-aided positioning and navigation of dynamic applications.

Low-SWaP alternative to Fiber Optic Gyros (FOG)

Our GYPRO® digital MEMS gyroscopes feature a 24-bit digital SPI interface that speeds-up their integration compared to conventional analog sensors. The in-house factory calibration removes the need for costly and complex temperature modeling and compensation at system-level. For applications where safety matters, the digital interface integrates an initial self-test as well as a unique continuous in-operation self-test.

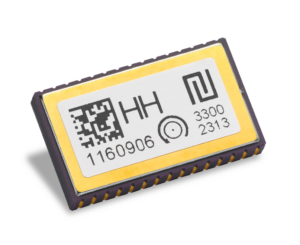

Contrary to expensive and bulky solutions like FOG (Fiber Optic Gyros) and DTG (Dynamically Tuned Gyros), our high stability digital MEMS gyros are housed in a miniature hermetic SMD package that reduces the overall SWaP-C (Size, Weight, Power and Cost).

For applications requiring both high precision angular rate and acceleration measurement with high stability, the GYPRO® gyroscopes are ideally complemented by our AXO® closed-loop digital MEMS accelerometers sensors that feature the same digital interface and SMD package, paving the way to a new generation of low-SWaP high performance multi-axis sensors solutions.

Key features

- 1-axis yaw rate gyro (Z-axis)

- Closed-loop architecture for best-in class linearity

- 24-bit digital SPI interface

- Hard-coded electronics, no software

- Initial and continuous self-test

- Hermetic ceramic SMD package

- Factory-calibrated

- Non classified under dual-use export control

| Performance / Typical values | Unit |

GYPRO®4300 |

GYPRO®4050

|

GYPRO®3300

|

GYPRO®2310 GYPRO®2300

|

|---|---|---|---|---|---|

| Input Range | °/s | ±300 | ±50 | ±300 | ±300 |

| Bias instability (Allan variance) | °/h | 0.4 (typ) 2 (max) |

0.2 (typ) |

0.8 | 0.8 |

| Angular Random Walk | °/h | 0.07 | 0.02 (typ) |

0.15 | 0.14 |

| Bias in-run stability | °/h | 7 | 7 | 10 | 30 |

| Bias run to run repeatability | °/h | 10 | 10 | 10 | 10 |

| Residual bias temperature error (1 σ) | °/h | 40 | 40 | 72 | 45 |

| Scale Factor non linearity | ppm | 60 | 200 | 100 | 70 |

| Scale Factor run to run repeatability | ppm | 60 | 60 | 25 | 100 |

| Residual Scale Factor temperature error (1 σ) | ppm | 160 | 600 | 400 | 500 |

| Vibration Rectification Error | °/h/g² | 0.5 | 1 | 0.5 | 30 |

| Vibration range (operation) | grms | 8 [20-2000Hz] | 8 [20-2000Hz] | 8 [20-2000Hz] | 4 [20-2000Hz] |

| Bandwidth | Hz | >200 | 30 | >200 |

>200 100 |

| Data Rate | Hz | 1800 | 220 | 1700 |

1700 200 |

| Latency | ms | <1 | 40 | 1 |

2 40 |

| Size (L x l x h) | mm | 12 x 12 x 5.5 | 12 x 12 x 5.5 | 19.6 x 11.5 x 2.9 | 19.6 x 11.5 x 2.9 |

| Package | 28 pins J-Lead | 28 pins J-Lead | CLCC 30 | CLCC 30 | |

| Status | Production | Prototypes | Not Recommended for New Designs | End of Life |

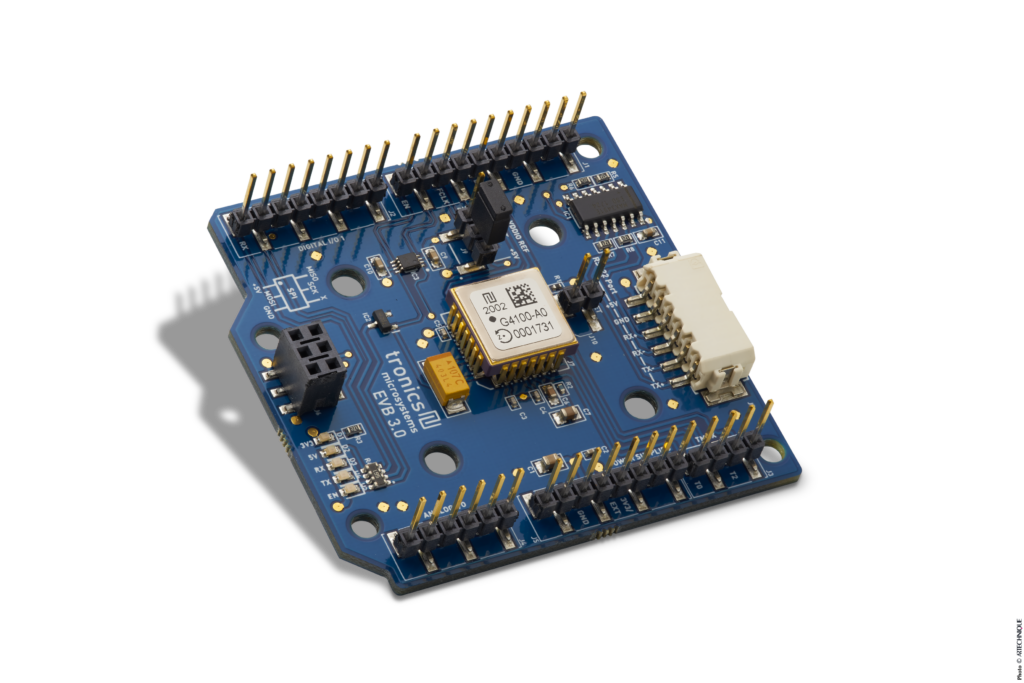

MEMS Gyros Evaluation Boards

To speed-up the evaluation of our GYPRO® MEMS precision gyros, Tronics has designed the GYPRO®-EVB3, an evaluation board compatible with Arduino Leonardo platform. Simply plug your Arduino board on the GYPRO®-EVB3, connect the USB interface and download Arduino.

GYPRO® Evaluation Board

Let's talk about your project !

MEMS gyros evaluation tools tutorials

Evaluation Tool – Tutorial – Installation and Programmation of the Evaluation Kit

Evaluation Tool – Tutorial – Software